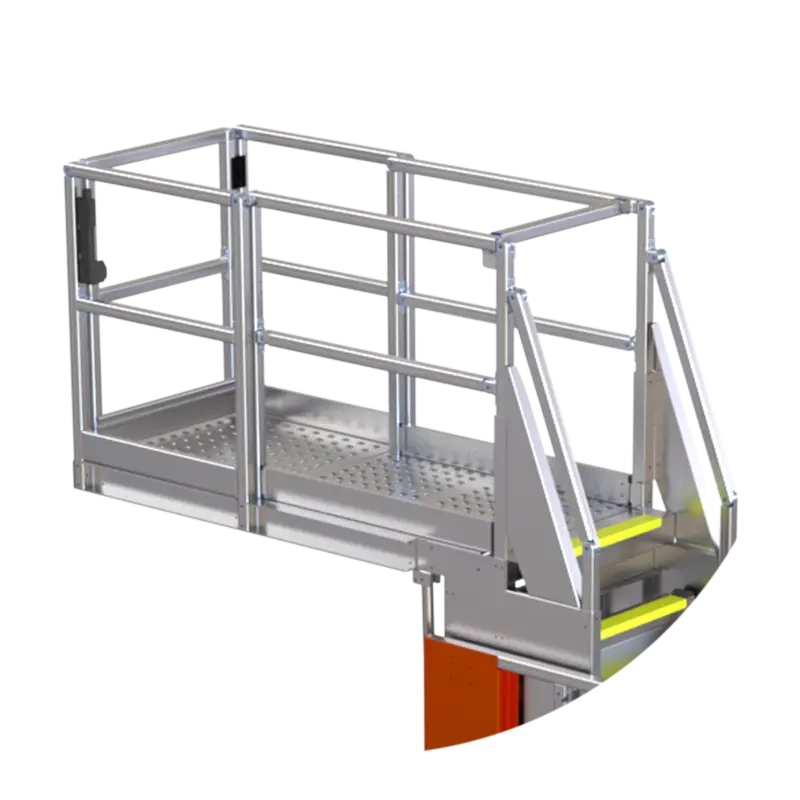

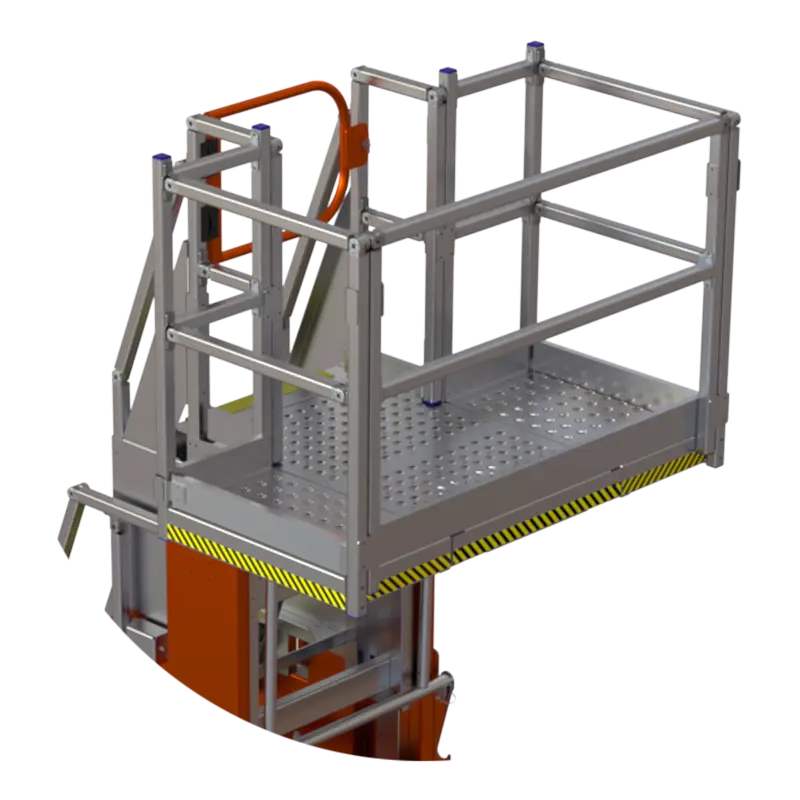

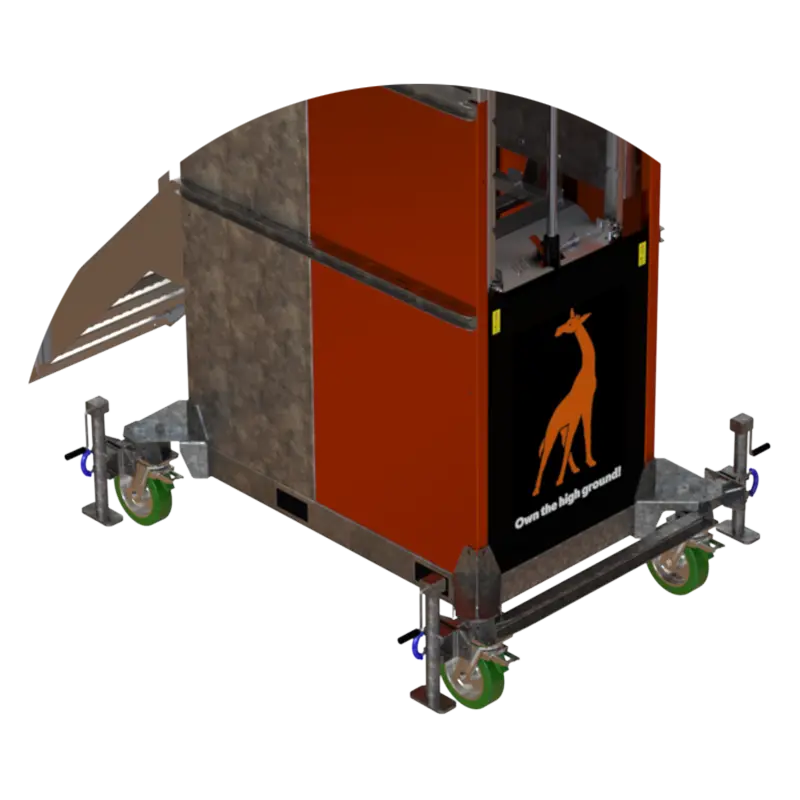

Equiptec AHP (example model shown is G20)

Equiptec AHP (example model shown is G20)

Maintenance team morale booster

…and they will respond with safer work practices and faster turnaround…meaning less downtime for your profit producing gear and less stress over potential accidents.

The Equiptec AHP delivers the above with simple, rapid deployment and a strong, sturdy working platform at the right ergonomic height. Maintenance staff love it!

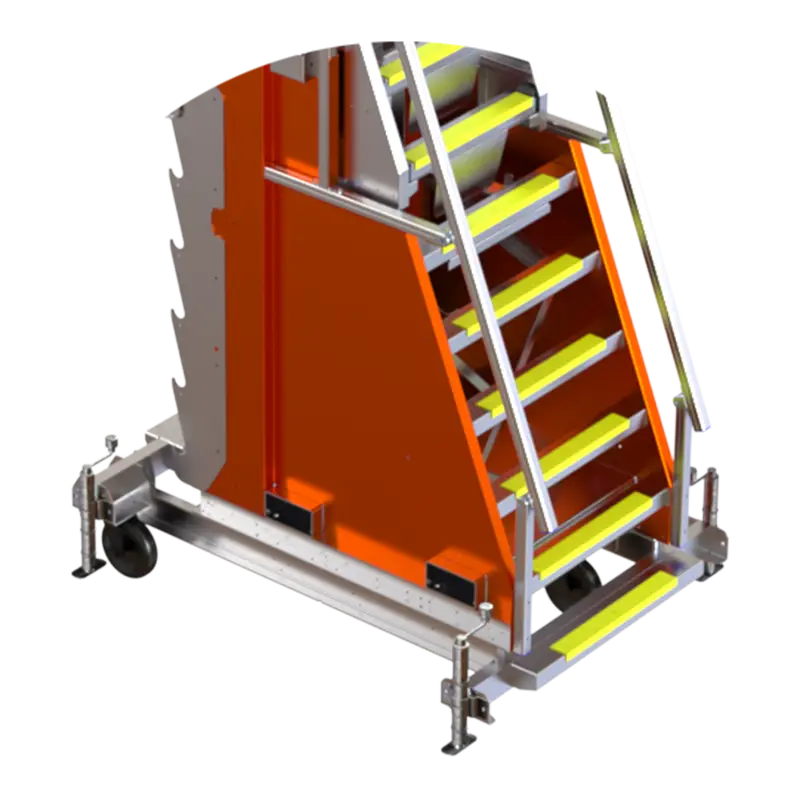

- Fast height adjustment

- Deck cantilever distance remains constant

- Wide, easy climb anti-slip treads with constant pitch throughout adjustment range

- No vertical climbing

- Huge range of options (all can be retrofitted)

| Elevated Work Platforms | Equiptec AHP (example model shown is G20) | |

|---|---|---|

|

||

| INITIAL COST |

In most cases, Elevated Work Platforms (EWP) will be more expensive than other options. |

Adjustable Height Platforms (AHP) are less expensve than most EWP. |

| ABILITY TO REACH OBJECTIVE |

There is a huge variation of types/models built for different applications, but EWP viewed as a whole, can be used to reach the vast majority of work situations. |

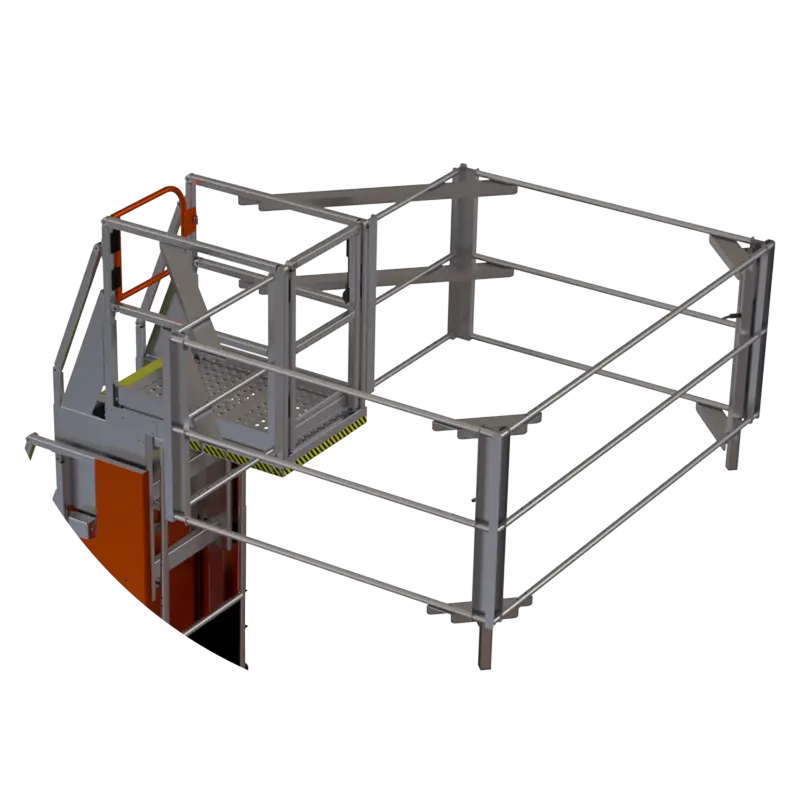

Equiptec AHP can adapt to many different situations by having a large range of retrofittable options. These options can be used to increase Cantilever distance, deck width, deck height etc. as well as add more features such as Barrier systems, multiple direction access gates etc. Not all brands offer these capabilities. |

| MAINTENANCE REQUIREMENTS |

EWP are far and away the most expensive option for maintenance because they

|

Although some AHP brands utilise complex systems which include high maintenance sliding faces, winches etc. Equiptec AHP have very few moving parts and consequently very little maintenance requirements. It is a good idea to check out the Manufacturers Instruction Manuals to ensure they are comprehensive. AHP require considerably less maintenance than EWP. |

| REGULATORY COMPLIANCE REQUIREMENTS |

Compliance is another big issue for EWP because they

|

Compliance is not easy for AHP as Standards have not been developed to cover this relatively new concept yet. Check that the Manufacturer has made some effort to comply with the design (handrail heights etc.), stability and strength requirement sections of an appropriate Standard. Equiptec AHP may go well beyond these, but compliance with these basic requirements would be essential for any reputable supplier. |

| TRANSPORT AND DEPLOYMENT REQUIREMENTS |

EWP:

|

Some AHP’s are very large and difficult to transport, while some are small and compact, and therefore easy to move around. Ease of transport and deployment will again vary between brands. Equiptec AHP produce some very large units that “fold down” to a more manageable size/shape for transport/storage. Watch this capability as if a brand cannot do this, it may incur a lot of cost to get them to your site. Once on site, deployment should be reasonably easy. Equiptec AHP also produce options that allow for units to be used “off slab”, so its important to check you are getting the brand and options that accurately suit your needs. |

| STORAGE REQUIREMENTS |

EWP storage requirements are similar to most others, with the main exceptions being:

|

Most AHP are similar in size (but a lot lighter than) comparable EWP. However, they generally are easier to move around, do not require heavy duty foundations, or any refueling/recharging facilities. |

| STABILITY |

EWP tend to move and sway a lot, particularly at higher levels, so users need to accept this. Again, it is crucial to check the foundations will handle the increased point loading for all situations the EWP may produce (i.e. slewing around will quickly change the loadings on the ground bearing). Trained operators are essential given that any event at the height/reach that EWP get to, can quickly turn catastrophic. |

Equiptec AHP comply with the applicable 'strength and stability' requirements of major international standards. Some Brands do not place importance on this, so while they are “safe” they may feel quite unstable at higher positions which makes users uncomfortable. AHP tend to be susceptible to wind, so take care when using them outside. |

| ADAPTABILITY |

EWP is the ultimate in adapting to difficult elevated working positions, but it must be remembered that this is simply access to work within the confines of the EWP cage. EWP is not designed for use as egress on to an elevated surface. |

AHP are adaptable by the very fact that they adjust to suit work at different heights. EWP will give you a bigger height adjustment range, but Equiptec AHP also have the ability to retrofit a variety of accessories to suit many different situations. Other methods can't do this and this makes Equiptec AHP truly versatile. |

| EASE OF USE |

EWP is more complex to operate. Training is required to know how to deal with all the mechanical systems, and in using Fall Arrest equipment (which must be checked/certified as fit for purpose). EWP can be used to take items up to the work face, but you must be able to get these into the cage safely first, and then climb in yourself with Harness equipment already fitted. This could be difficult, depending on the EWP type. Scissor Lifts require a vertical climb to get into the Deck area, which is not easy, or particularly safe. And if you have 2 or more people in the cage at height, and 1 needs to go down for any reason, all must go down. |

AHP outperform EWP for ease of use on low level height work. This because of:

|

AHP Capabilities

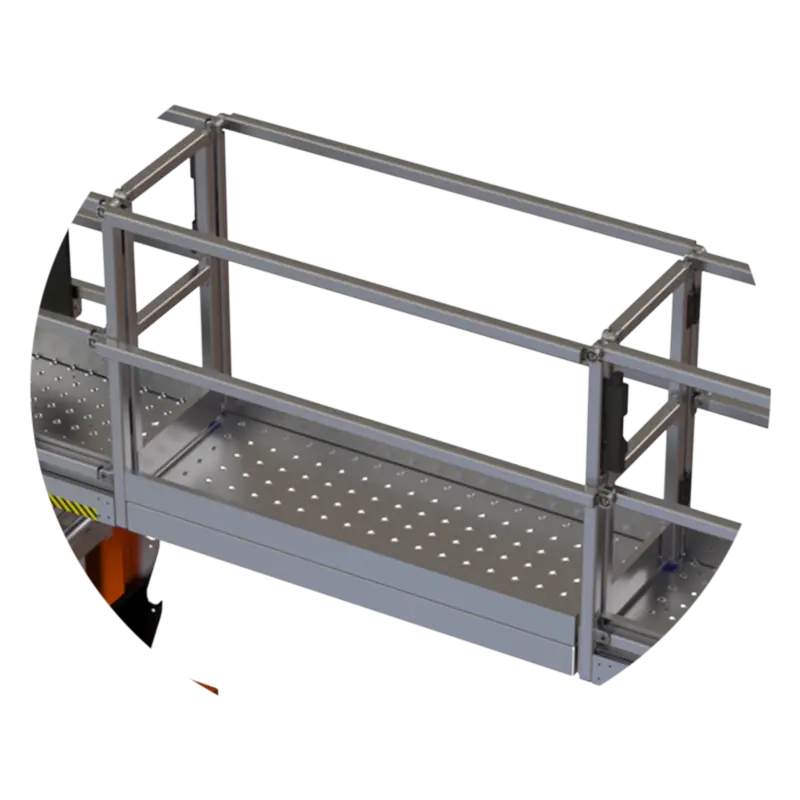

Key Product Features

Extra tough,

Room to work

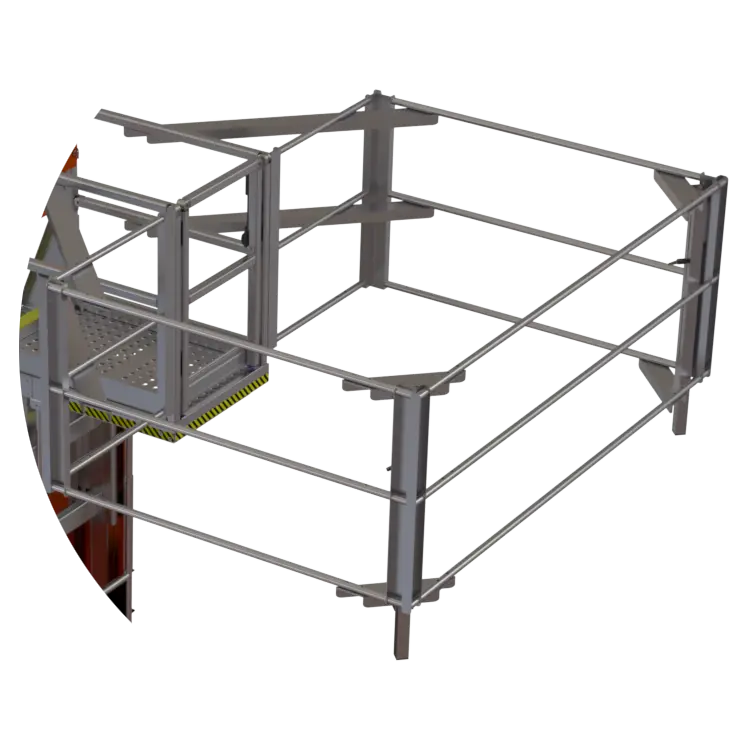

Full size access gates

Convenient solid rear gate,

Easy to climb

Fits multiple jobs

Rapid

Easy to climb

Fits multiple jobs

Rapid

Massive number of configurations from 3 core ranges

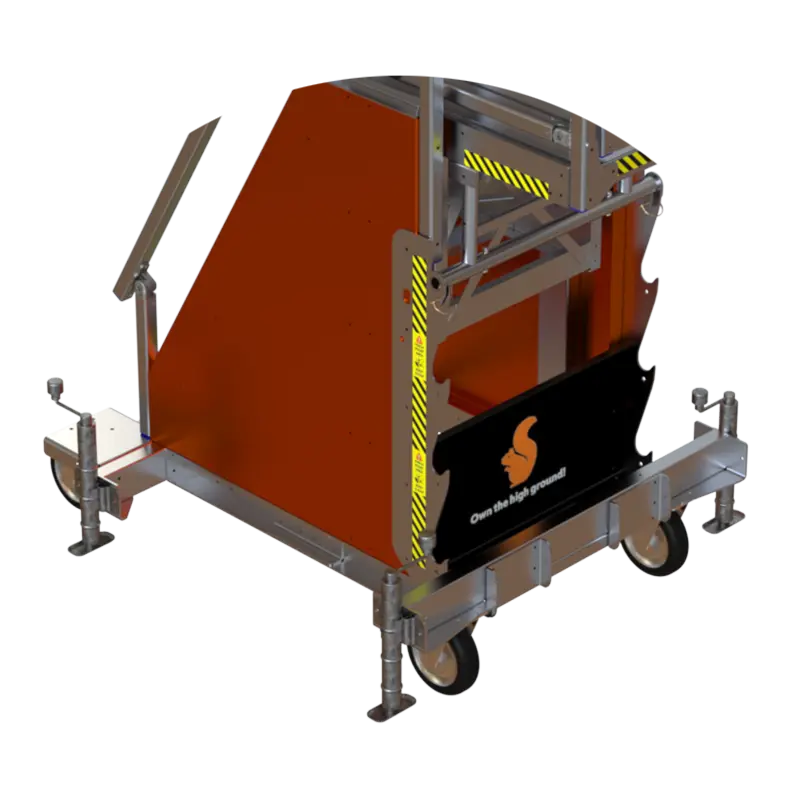

Squirrel

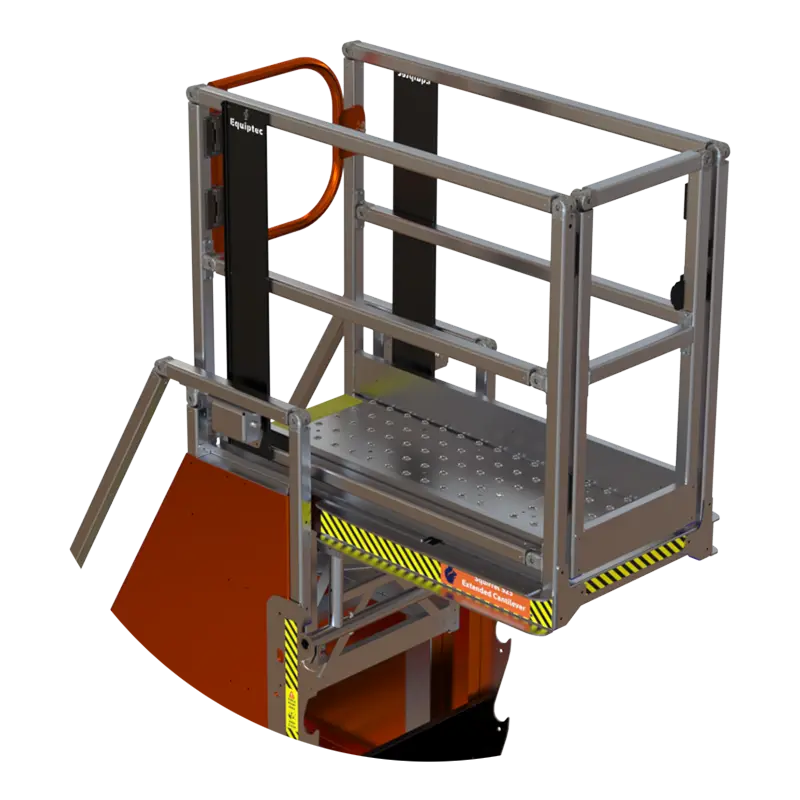

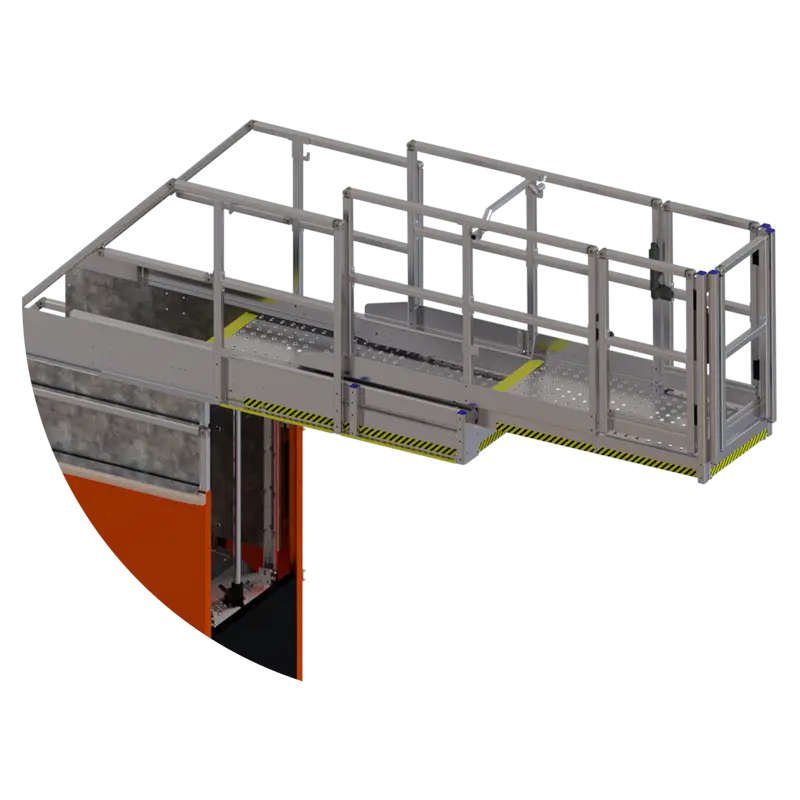

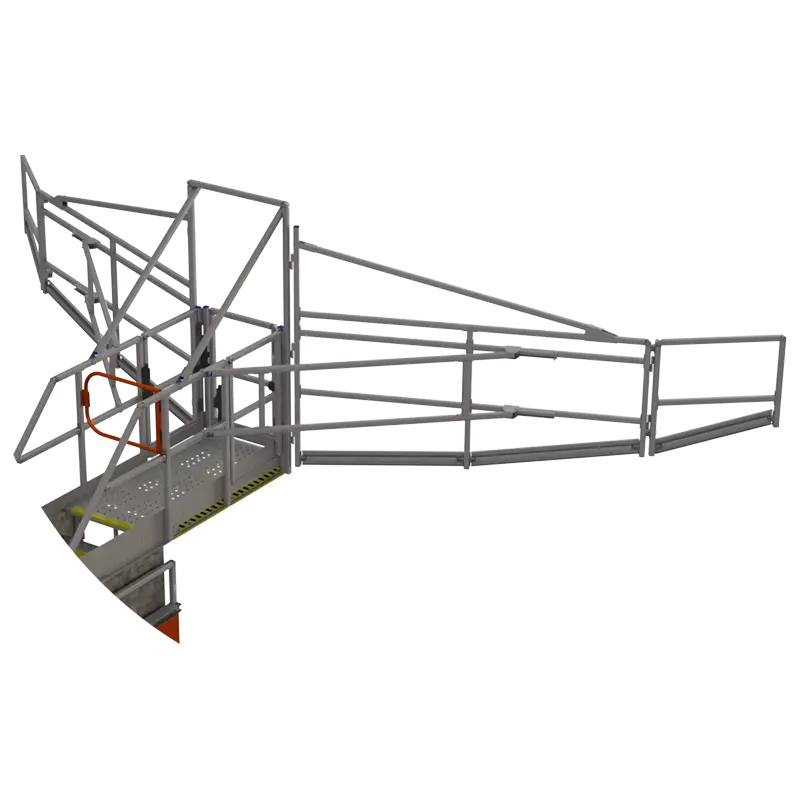

Extended Cantilever

All Terrain

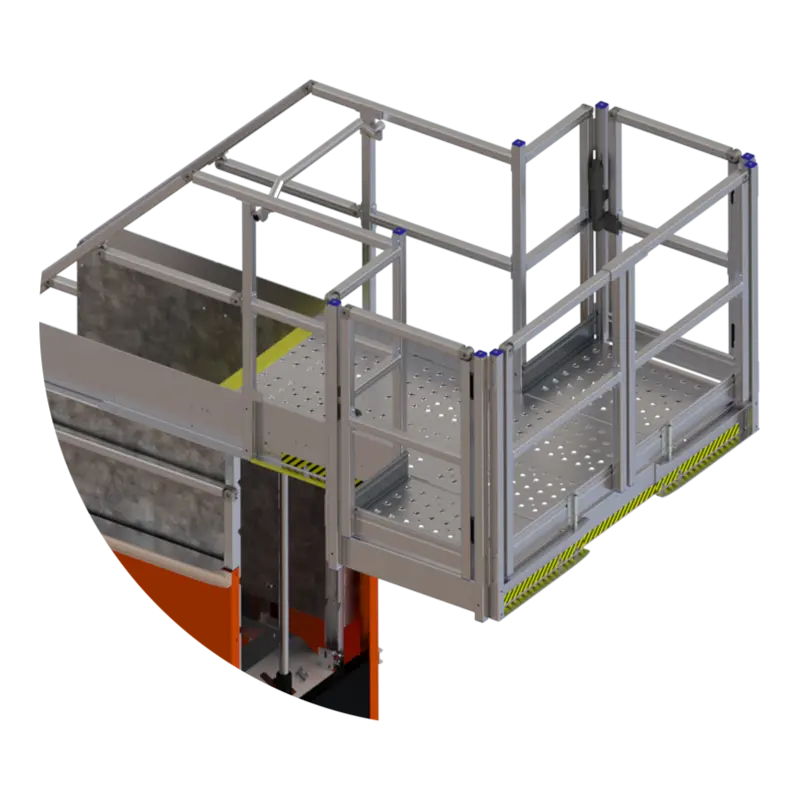

Safety Cell

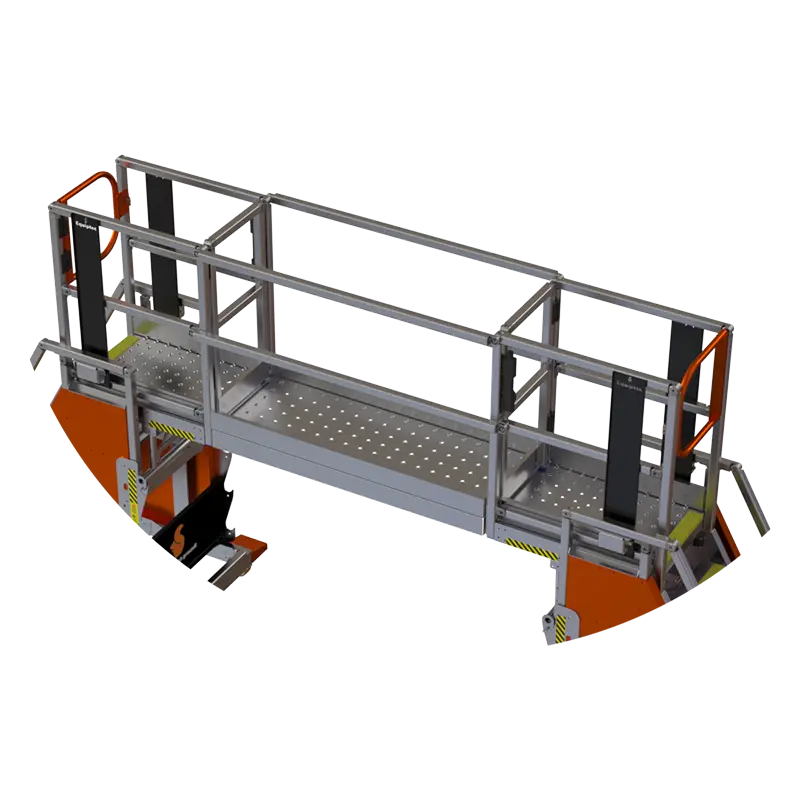

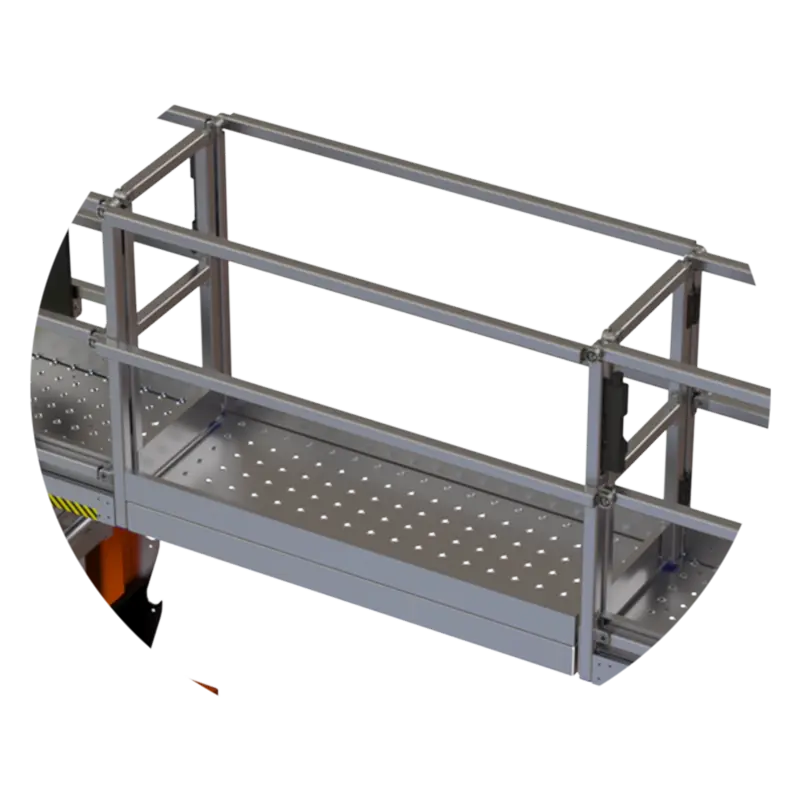

Bridge

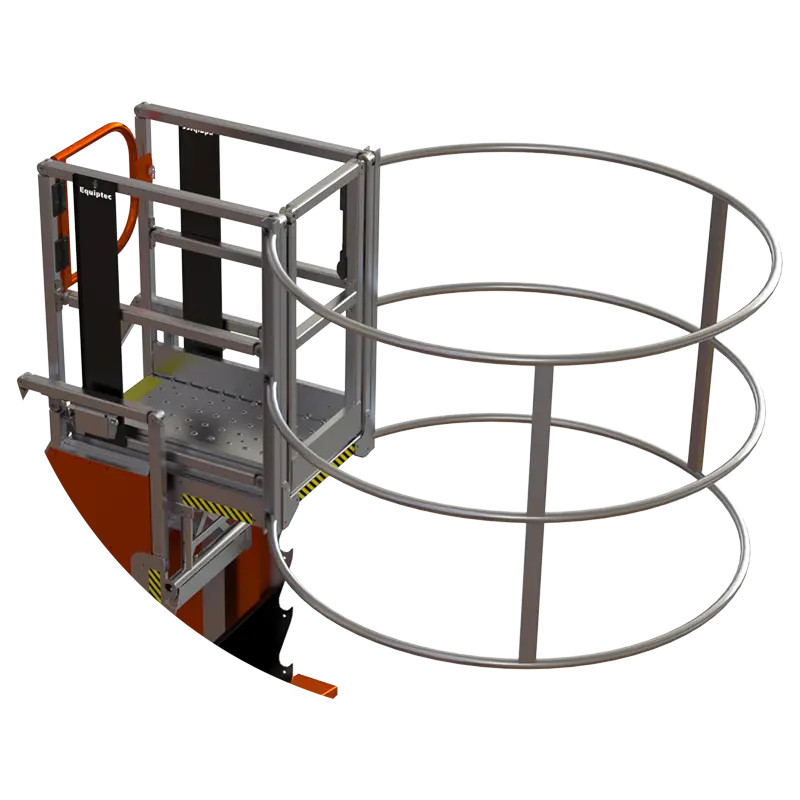

Monkey

Extended Cantilever

Hammerhead

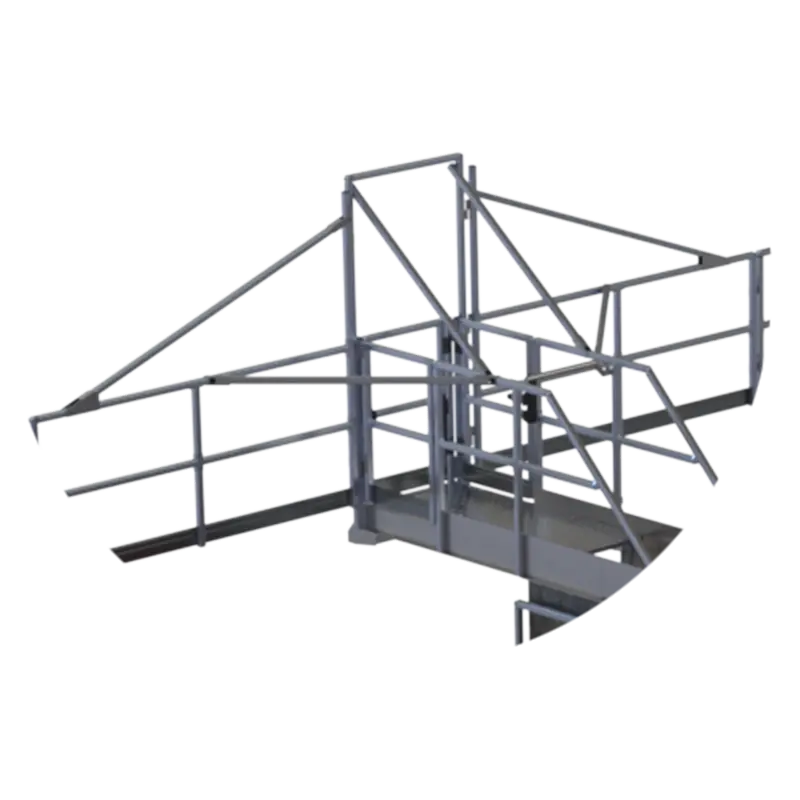

All Terrain

Safety Cell

Trailer

Bridge

Swing Gates

Custom Deck

Giraffe

Slide Out

Hammerhead

All Terrain

Swing Gates

Safety Cell

Bridge

Trailer

Custom Deck